AI in manufacturing is changing the way products are created, leading to increased efficiency and reduced costs.

As industries evolve, adopting AI technologies becomes crucial for staying competitive.

This article delves into how AI is revolutionizing manufacturing, the benefits it offers, and the challenges companies face when integrating AI solutions.

Join us as we explore case studies and future trends in the manufacturing sector.

Understanding AI and Its Role in Manufacturing

Understanding AI and Its Role in Manufacturing

Artificial Intelligence (AI) is transforming manufacturing by enabling smarter operations. Through data analysis and machine learning, factories can predict maintenance needs and optimize production lines.

AI systems can analyze vast amounts of data quickly, leading to better decision-making and reduced downtime. By integrating AI, manufacturers can enhance quality, improve safety, and reduce waste.

This technology is not just a trend; it’s essential for companies looking to remain competitive in a fast-paced market.

Key Benefits of AI in Manufacturing

Key Benefits of AI in Manufacturing

Implementing AI in manufacturing offers significant advantages. First, it enhances productivity by automating routine tasks. This allows workers to focus on more complex problems that require human insight.

Second, AI helps in predictive maintenance, reducing downtime and saving costs. Factories can monitor equipment in real-time to predict failures before they happen.

Third, quality control becomes more accurate with AI-powered visual inspection systems. These systems can detect defects that human eyes might miss.

Additionally, AI assists in supply chain optimization by analyzing data trends for better inventory management. Overall, embracing AI technology can lead to smarter operations and increased profitability.

AI Technologies Transforming Production Lines

AI Technologies Transforming Production Lines

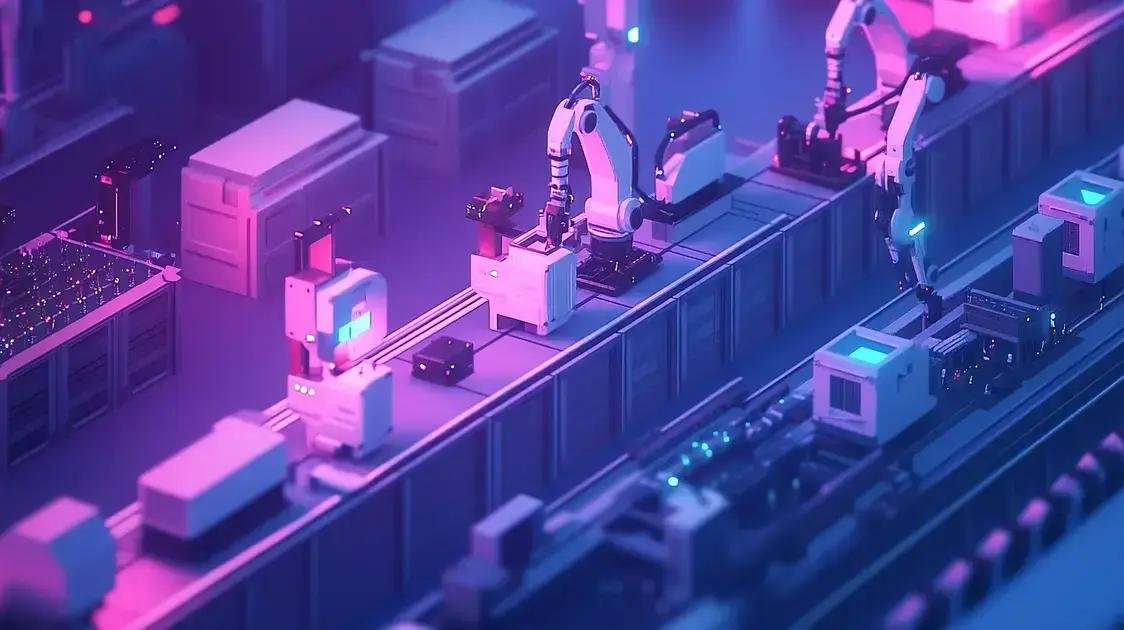

AI technologies are reshaping production lines in various impactful ways. One major innovation is the use of robotic process automation (RPA), which increases efficiency by performing repetitive tasks without fatigue.

Another significant technology is machine learning, allowing systems to learn from past data and improve processes over time. Computer vision systems enable machines to inspect products in real-time, ensuring high-quality standards.

Additionally, IoT integration provides valuable data from connected devices, helping manufacturers make informed decisions. Overall, integrating these AI technologies leads to increased operational efficiency, reduced waste, and higher quality outputs in manufacturing environments.

Challenges in Implementing AI in Manufacturing

Challenges in Implementing AI in Manufacturing

While AI offers great potential, implementing it in manufacturing comes with challenges. One major issue is the high initial costs associated with AI technologies. Companies may need to invest significantly in new equipment and training.

Another challenge is data integration; existing systems often have data in different formats, making it hard to analyze comprehensively.

Resistance to change is another hurdle. Employees may feel threatened by automation or may not fully understand how to utilize AI tools effectively.

Additionally, cybersecurity risks increase as manufacturing becomes more connected. Addressing these challenges requires thoughtful planning, training, and ongoing support to realize the full benefits of AI.

Future Trends of AI in Manufacturing Industry

Future Trends of AI in Manufacturing Industry

The future of AI in manufacturing looks promising with many exciting trends emerging. One key trend is the increased use of automation. Manufacturers are looking to automate more processes to boost efficiency and reduce costs.

Another trend is the growth of predictive analytics. By using AI to analyze data, companies can predict market demands and adjust production schedules accordingly.

Furthermore, collaborative robots, known as cobots, are becoming more common. These robots work alongside humans to improve safety and efficiency on the shop floor.

Finally, the integration of blockchain technology with AI can enhance supply chain transparency and security. As these trends evolve, AI will play a critical role in shaping the future of the manufacturing industry.

Case Studies: Successful AI Adoption in Factories

Case Studies: Successful AI Adoption in Factories

Many factories have successfully integrated AI to enhance operations. For example, a prominent automotive manufacturer utilized AI for predictive maintenance, reducing machinery downtime by 30%. This led to significant cost savings and increased productivity.

Another case is a consumer goods company that implemented AI-driven quality control systems. These systems used computer vision to detect defects in real-time, improving product quality by 20%.

Additionally, an electronics manufacturer adopted machine learning algorithms to optimize supply chain logistics, resulting in a 15% reduction in inventory costs. These examples highlight the tangible benefits and efficiencies that AI can bring to manufacturing environments, paving the way for further advancements in the industry.

Conclusion: Embracing AI in Manufacturing

In conclusion, the integration of Artificial Intelligence (AI) in manufacturing is transforming the industry. From enhancing productivity to improving quality control, AI has proven its value across various sectors.

Manufacturers are encouraged to take a gradual approach when implementing AI technologies, starting with clear objectives and small pilot projects to gauge effectiveness.

By learning from successful case studies, businesses can leverage AI not only to streamline their operations but also to gain a competitive edge in an evolving market.

Ultimately, the potential of AI to reshape manufacturing is immense, paving the way for innovation and efficiency that can drive future success.

FAQ – Frequently Asked Questions About AI in Manufacturing

How can AI improve productivity in manufacturing?

AI automates repetitive tasks, allowing workers to focus on more complex issues, thus enhancing overall productivity.

What are some key benefits of AI in manufacturing?

Key benefits include predictive maintenance, improved quality control, and optimized supply chain logistics.

What AI technologies are currently being used in factories?

Technologies such as machine learning, computer vision, and robotic process automation are transforming production lines.

What challenges might companies face when implementing AI?

Challenges include high initial costs, data integration issues, employee resistance to change, and cybersecurity risks.

What future trends should we expect from AI in manufacturing?

Expect increased automation, growth in predictive analytics, and the use of collaborative robots working alongside human workers.

Can you provide examples of successful AI adoption in factories?

Yes, companies have successfully implemented AI for predictive maintenance, quality control, and supply chain optimization, resulting in significant efficiency gains.